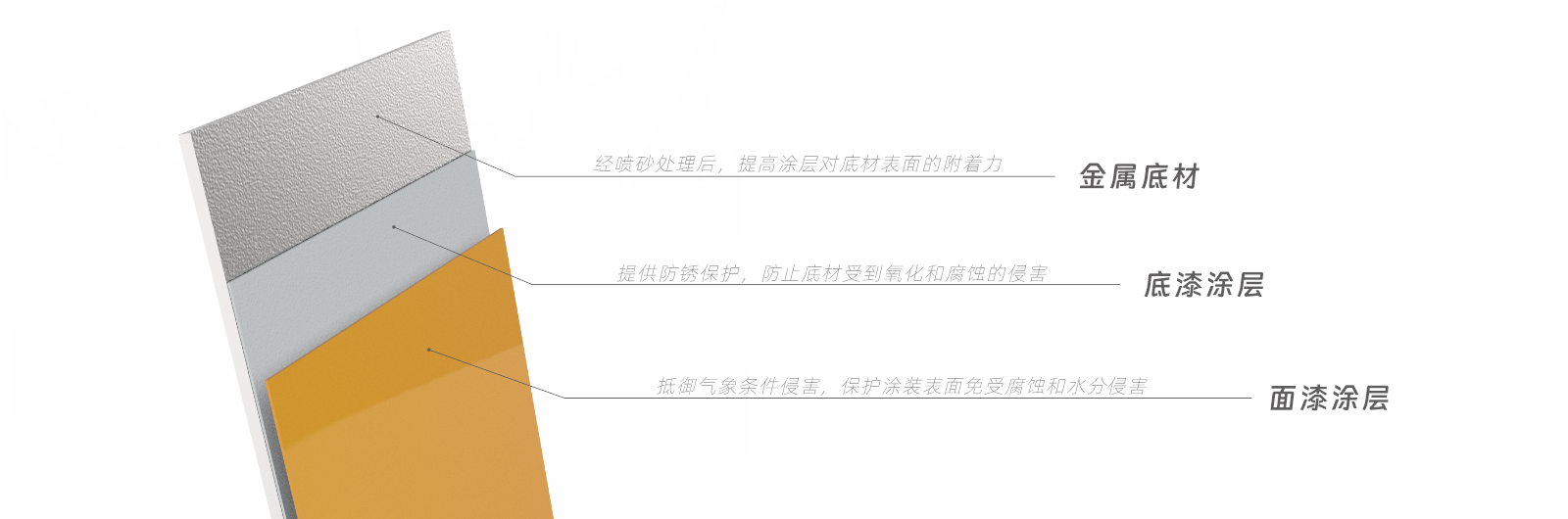

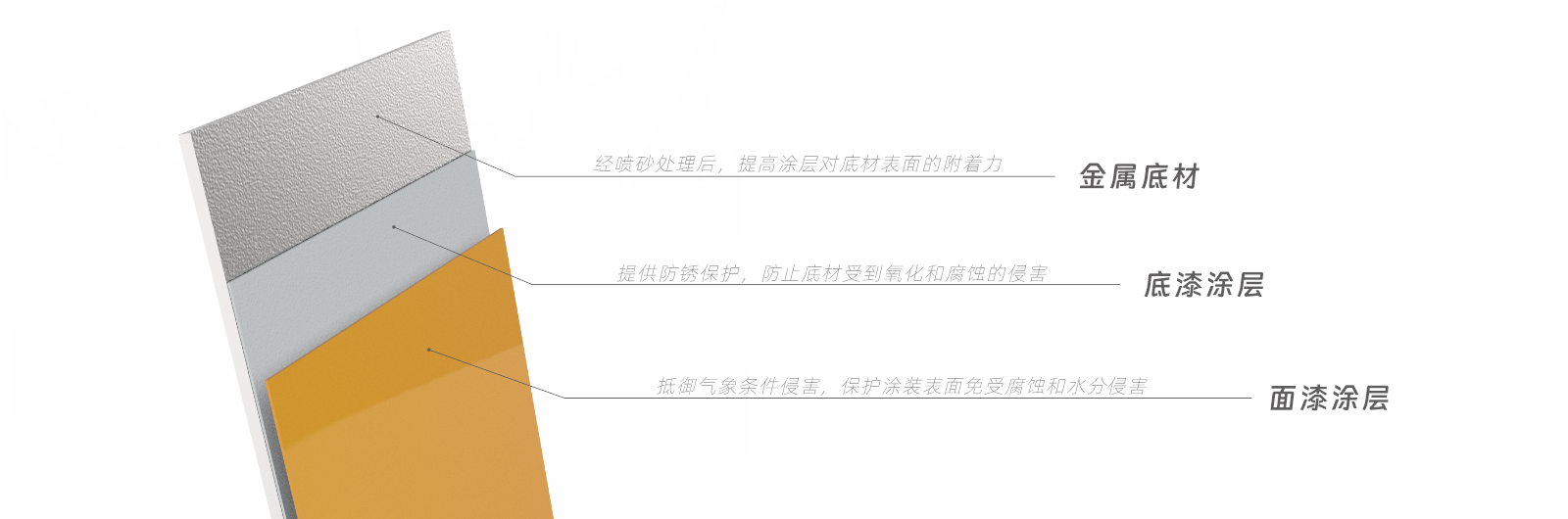

Product Features

Excellent adhesion to substrates including stainless steel, aluminum alloy, galvanized steel and aluminum plating, with pull-off adhesion reaching 4MPa.

The coating is corrosion-resistant and can effectively resist acid, alkali, salt, seawater and other media corrosion.

The thick-coat application is less prone to sagging, and it is more capable of covering up than traditional epoxy primer products. It also helps reduce the cost of topcoat.

Performance Advantages

| Performances | Light Metal-Specific Primer | Epoxy Zinc Yellow Primer | Vinyl Phosphating Primer |

| Substrate Adhesion | ★★★★★ | ★★★ | ★★ |

| Chemical Resistance | Excellent | Excellent | General |

| Construction Performance | Gray color, easy to cover with topcoat, can be applied in thick coats | Yellow color, not easy to cover with topcoat, high paint consumption | Slightly yellowish color, thin and not thick coating |

Applications

Light Metal-Specific Primer - A specialized primer product designed for use on stainless steel, aluminum alloy, and galvanized steel substrates.

The product features strong adhesion and excellent chemical corrosion resistance, making it suitable for anti-corrosion coating on stainless steel containers, aluminum alloy profiles, and thermal-sprayed zinc/aluminum substrates.

Technical Parameters

| Color | Gray |

| Volume Solid | 40% |

| Flashpoint | Above 42°C |

| Coating film thickness | Dry film: 40-60 μm/coat Wet film: 103-154 μm/coat |

| Theoretical Coating Rate | 0.354 kg/m2/50 μm |

Coating System

Can be directly applied to stainless steel, aluminum alloy, and galvanized substrates, and can be used with various topcoats according to different application scenarios.

Immersion Service System: Light Metal-Specific Primer + Oil/Water-Resistant Epoxy Coating

Outdoor Weathering System: Light Metal-Specific Primer + Acrylic Polyurethane Topcoat/Fluorocarbon Topcoat

Application Methods

Application Temperature:5℃~40℃

Mixing: Use power tools or manual tools to stir thoroughly until uniform.

Mixing Ratio: Base/Hardener = 9:1 (by weight)

Pot Life: Airless spraying, air spraying, brushing, or rolling (specialized).

Construction method | Nozzle Size | Outlet Pressure | Dilution ratio (mass ratio) |

Airless Spray | 0.33mm-0.43mm | 10-15Mpa | 4-10% |

Air Spray | —— | —— | 15-25% |

Brushing, Rolling | —— | —— | 10-15% |

Thinner: | Epoxy thinner |

|

|

Drying Time & Coating Interval

Temperature | 5℃ | 20℃ | 30℃ |

Dry Fingers | 5hrs | 1hr | 30mins |

Semi-hard drying | 36hrs | 16hrs | 8hrs |

Minimum Coating Interval | 36hrs | 16hrs | 8hrs |

Surface Treatment

Metal surface without sandblasting, no need to sand, use organic solvents to wipe, remove the surface oil can be, there are rusty places to sand clean, save the sandblasting sanding labor and material costs, the surface treatment method is simple.

Safety Measures

1. Avoid contact with skin and eyes.

2. If paint comes into contact with skin, wash with warm water or an appropriate cleaning agent. If paint comes into contact with eyes, rinse thoroughly with water and seek medical attention immediately.

3. Ensure good ventilation.

4. The paint contains flammable substances. Keep away from sparks and prohibit smoking in the vicinity.

5. Comply with all health and safety regulations on-site.

Storage

Store in a dry and cool environment, away from heat sources and open flames. Keep the container tightly sealed.

Shelf life: 12 months from the date of production (at 25°C).

Attention

Since the conditions of product use are beyond our control, the information provided here does not constitute a warranty. We are only responsible for the selection of products. Due to the continuous development of our products and production processes, the content of this manual may be updated at any time. All information herein is subject to our confirmation. Before using the product, please ensure that you have the latest version of the manual.