High-Temperature Paint Application Method

High-Temperature Resistant Paint is a specialized coating that maintains excellent performance under high-temperature conditions, widely used in high-temperature sections of equipment in industries such as metallurgy, aviation, and power generation.

Its applications include blast furnaces in steel plants, the outer walls of hot blast stoves, high-temperature chimneys, flues, high-temperature gas pipelines, heating furnaces, and heat exchangers.

This type of paint is characterized by its high-temperature resistance and superior mechanical properties.

The correct application method is crucial to ensuring its protective effectiveness and service life.

Below is a detailed introduction to the application method of high-temperature resistant paint.

一、Scope of Application

High-Temperature Resistant Paint is primarily used for protective coating on high-temperature facilities. Its scope of application includes, but is not limited to:

- Metallurgical equipment: Such as blast furnaces and the outer walls of hot blast stoves.

- Power facilities: Such as high-temperature chimneys, flues, and high-temperature gas pipelines.

- Industrial equipment: Such as heating furnaces and heat exchangers.

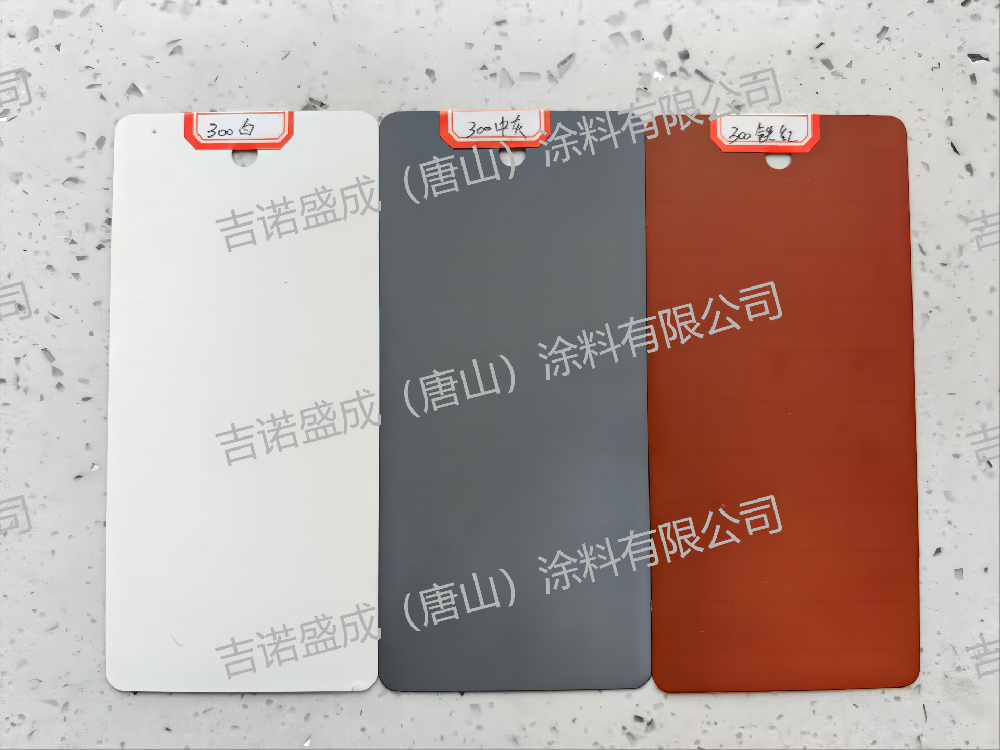

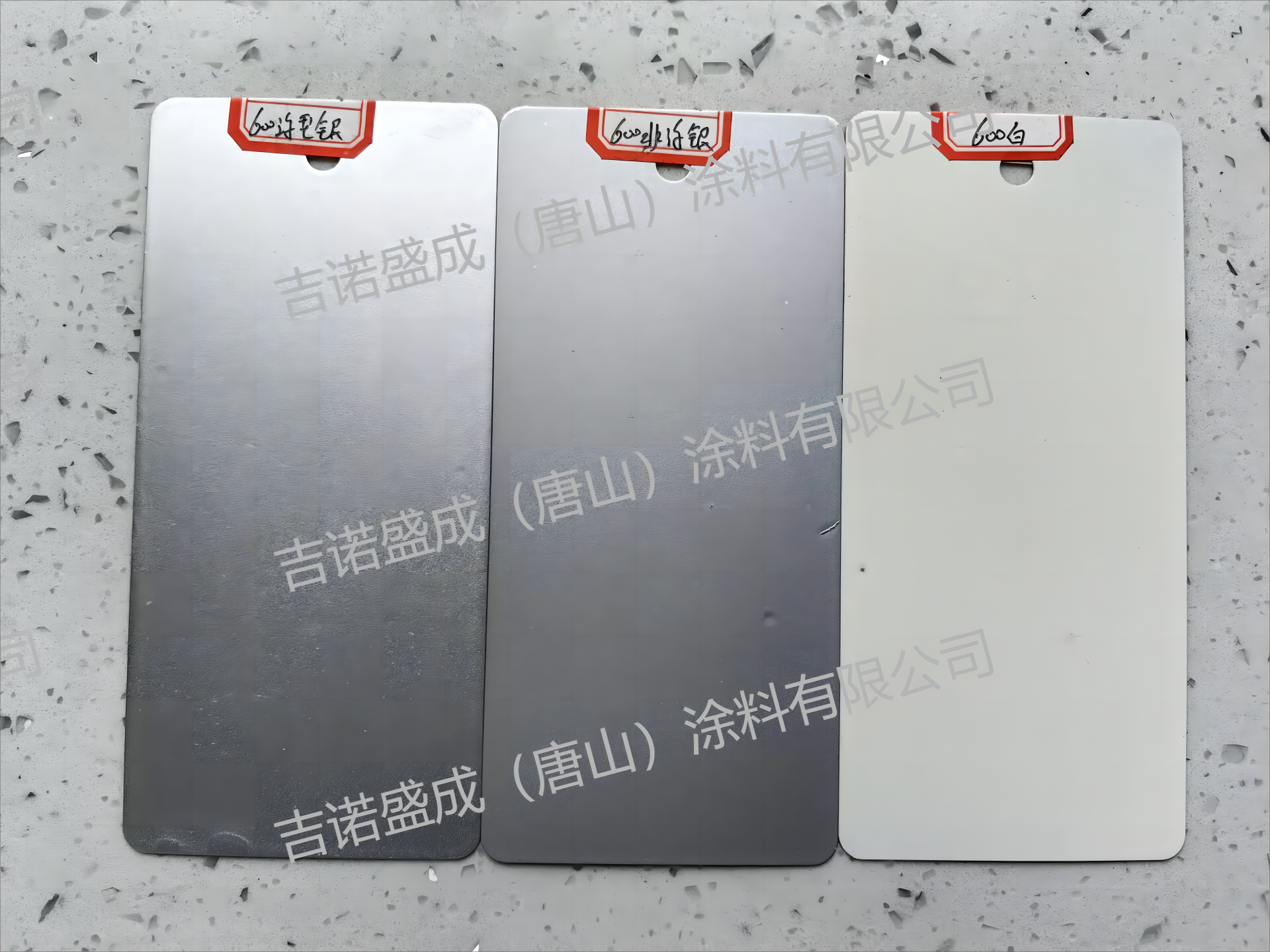

Different types of high-temperature resistant paints may have varying applicable temperature ranges, so it is essential to select the appropriate variety.

二、Preparation Before Construction

1. Surface Cleaning

The surface to be coated must be clean, dry, and free of dust, grease, rust, or other contaminants. Specific steps include:

- Surface treatment: Use sandblasting to achieve the Sa2.5 rust removal standard, with a surface roughness of 30-70 micrometers.

2. Paint Preparation

Prepare the paint according to the instructions, ensuring thorough mixing. Pay attention to the following:

- Specialized thinner: Add an appropriate amount of specialized thinner to the high-temperature resistant paint and mix thoroughly to achieve the optimal viscosity for application.

- Avoid mixing: Do not use expired paint or mix paints from different brands.

3. Paint Mixing

Stir the paint thoroughly before use to ensure uniformity. An electric mixer is recommended for better results.

4. Container Sealing

Seal and store any unused portion to prevent moisture absorption or contamination.

三、Coating Process

1. Pre-Coating

For complex workpieces, pre-coat corners and edges in advance to prevent missed spots during application.

2. Coating Methods

High-temperature resistant paint can be applied using high-pressure airless spraying, conventional spraying, or manual brushing.

3. Coating Thickness

During spraying, typically apply 1-2 coats to achieve the specified film thickness. The dry film thickness of each coat should be controlled between 20-40 micrometers, with the total thickness meeting the design requirements.

四、Drying and Curing

1. Baking

After application, place the components into a baking oven for drying. Bake at 210°C for 40 minutes to ensure the paint is fully dried.

2. Large-Scale Facilities

For large-scale facilities, achieve high temperatures by operating the equipment, allowing the paint to fully cure.

By following the above steps and strictly adhering to the application method for high-temperature resistant paint, the protective performance and service life of the coating can be effectively ensured. Proper application not only enhances the coating's high-temperature resistance but also significantly extends the equipment's lifespan, providing reliable protection for facilities in high-temperature environments.