Product Features

Weather Resistance: Effectively withstands harsh environmental factors such as wind, rain, UV radiation, and acid rain, maintaining long-lasting brightness and color retention for over 15 years.

Chemical Resistance: Resistant to acids, alkalis, salt spray, and solvents, making it suitable for extremely harsh chemical environments.

Anti-Fouling and Self-Cleaning: The molecular structure of fluorocarbon paint provides extremely low surface energy, resulting in a smooth surface that resists dust and dirt adhesion.

Corrosion Resistance: Effectively blocks corrosive media from attacking the metal substrate, extending the service life of metal surfaces.

Aesthetic Appeal: Available in a variety of colors with high gloss, offering outstanding decorative effects that enhance the texture and beauty of metal surfaces.

Product Comparison

| Performances | Fluorocarbon Topcoat | Acrylic Polyurethane Topcoat | Polysiloxane Topcoat |

| Weather Resistance | Excellent | Good | Outstanding |

| Chemical Resistance | Excellent | Excellent | Excellent |

| Aesthetic Appeal | Beautiful & Vibrant | Beautiful & Vibrant | Beautiful & Vibrant |

| Application | Two-component | Two-component | Two-component |

| Price | ★★★★ | ★★★ | ★★★★★ |

Applications

Fluorocarbon topcoat is widely used for anti-corrosion and decorative coating on metal surfaces that are exposed to harsh environments for extended periods.

This includes:High-rise buildings.Television towers.Coastal facilities.Docks and piers.Bridges.Ships and vessels.Chemical equipment.Storage tanks.Pipelines.Valves.Oil drilling platforms.Marine equipment.Let me know if you need further assistance!

Technical Parameters

| Color | White & Various Colors |

| Volume Solid | 40% |

| Flashpoint | Above 26℃ |

| Coating Film Thickness | Dry film: 25-40 μm/coat

Wet film: 62.5-100μm/coat

|

| Theoretical Coating Rate | 0.154 kg/m2/40 µm |

| Gloss | High Gloss |

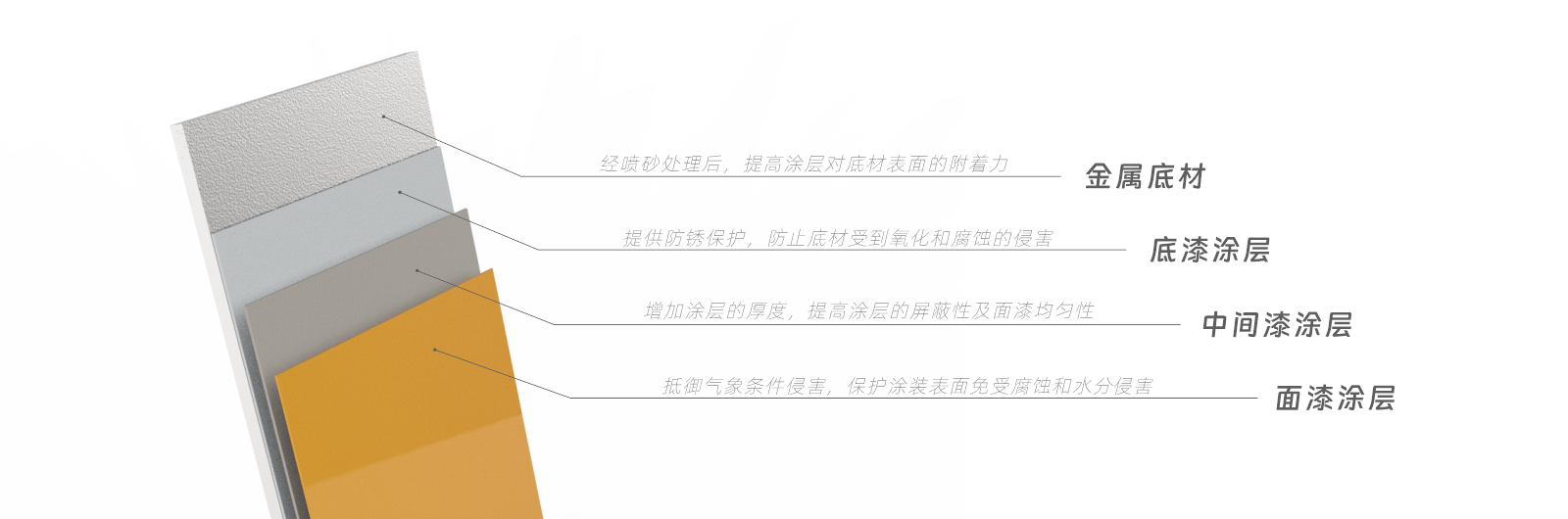

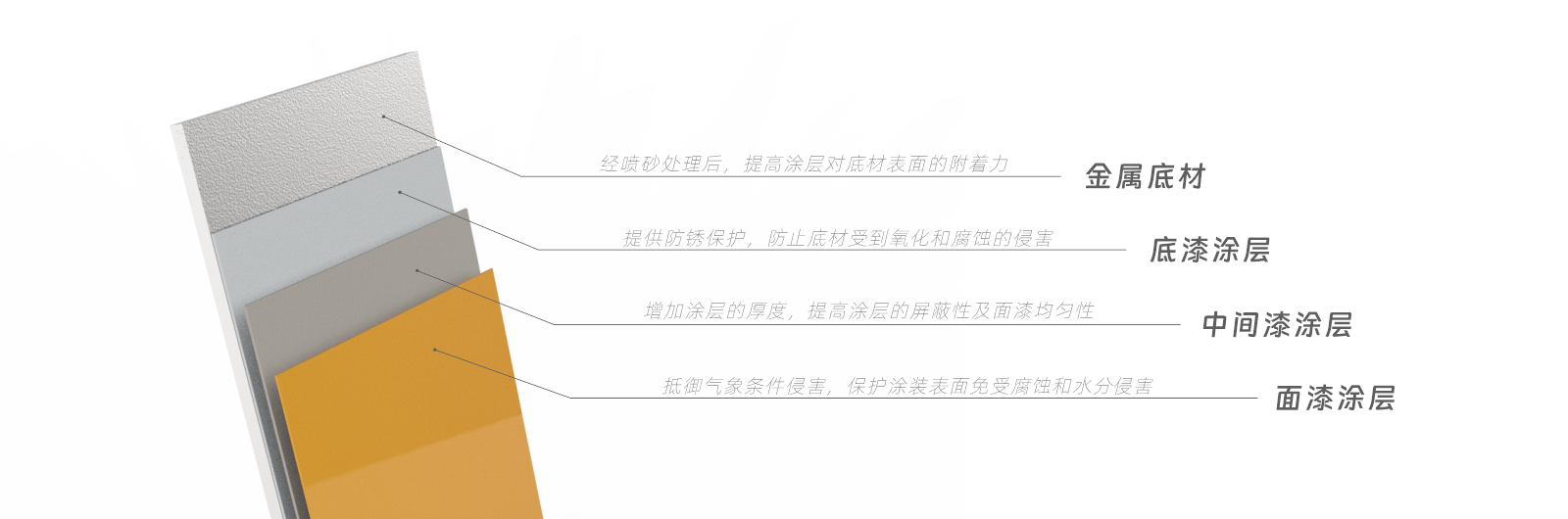

Coating System

To achieve optimal performance, it is typically necessary to use a complete coating system, including primers and intermediate coats.

For steel structures: Options include epoxy zinc-rich primer or epoxy primer.

For aluminum alloys: Options include zinc phosphate primer or specialized primers for light metals.

Construction Method

Construction temperature:0℃~40℃

Mixing: Use power tools or hand tools to mix well.

Mixing ratio: main agent/curing agent = 10/1 (quality ratio)

Mixed use period: airless spraying, air spraying, brushing, rolling (for special use)

| Construction Method | Nozzle Size | Outlet Pressure | Dilution Ratio (mass ratio) |

| Airless Spray | 0.33mm-0.43mm | 10-15Mpa | 6-10% |

| Air Spray | -----

| ----- | 20-26% |

| Brushing, Rolling | ----- | ----- | 10-20% |

Drying Time & Coating Interval

| Temperature | 5℃ | 20℃ | 30℃ |

| Dry Fingers | 1hrs

| 15mins | 10mins

|

| Semi-Hard Drying | 4hrs | 2hrs

| 1hrs |

| Minimmum Coating Inteinim | 24hrs | 24hrs | 10hrs |

| Maximum Coating Interval | 7days | 7days | 7days |

Surface Treatment :

The steel surface to be coated must be thoroughly cleaned of oil, scale, rust, and old coatings. This can be achieved through blast cleaning methods such as shot blasting or sandblasting, meeting the Swedish Standard Sa2.5, with a surface roughness of 30–70 μm. Alternatively, manual cleaning methods can be used to meet the Swedish Standard St3, with a surface roughness of 30–70 μm.

Safety Measures:

1、Avoid contact with skin and eyes。

2、When paint comes into contact with skin, wash with warm water or appropriate detergent. If paint comes into contact with eyes, flush with plenty of water and seek medical attention immediately.

3、Ensure good ventilation.

4、The paint contains combustible substances, please keep away from sparks and prohibit smoking in the immediate area.

5、All health and safety requirements will be observed on site.

Storage:

Store in a dry and cool environment, away from heat and ignition sources. The drum must be kept closed.

Storage period: 12 months from date of manufacture (25°C)

Attention:

Since the conditions of use of the products are beyond our control, the information contained herein is provided without warranty, i.e., the buyer is liable only for the selection of the products. Due to the continuous development of our products and production processes, the contents of this manual are subject to change at any time, and all information herein is subject to our confirmation. Please make sure that you have the latest version of this manual before using the product.