Product Features:

Good weather and water resistance: Suitable for long-term outdoor use, resistant to sunlight, rain, freeze-thaw cycles, and resistant to fading, discoloration, and chalking.

Good chemical and abrasion resistance: Withstands corrosion from chemical media such as acids, alkalis, salts, and oils, as well as mechanical wear and scratches.

Applications:

Metals:Steel, aluminum alloys, galvanized steel, etc.Wood:Wood panels, furniture, flooring, etc.

Plastics:ABS, PVC, PC, etc.Concrete: Walls, floors, ceilings, etc.

Technical Parameters

| Color: | Various colors |

| Gloss: | Glossy |

| Solid % | 40-48 |

| Flash Point |

Above 29°C |

| Film thickness |

Dry Film: 30-50 µm/coat; Wet Film: 70-125 µm/coat |

Theoretical Coverage |

0.160kg/m² /50 µm Actual coverage depends on surface preparation, environmental conditions, and application methods. |

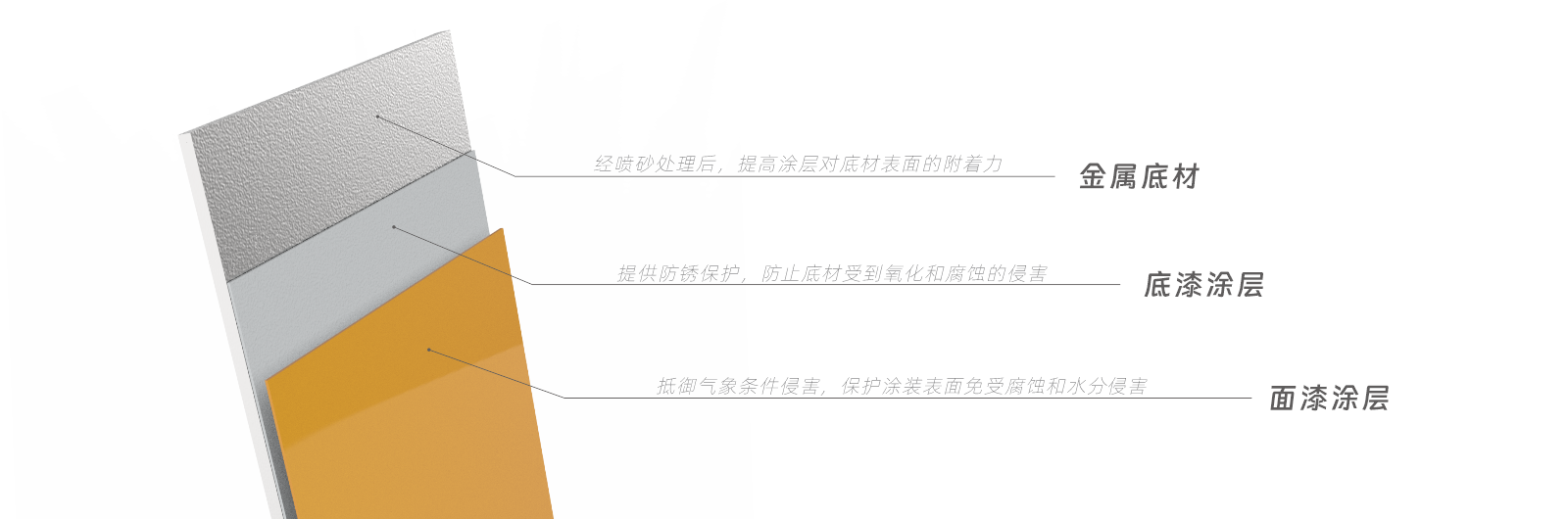

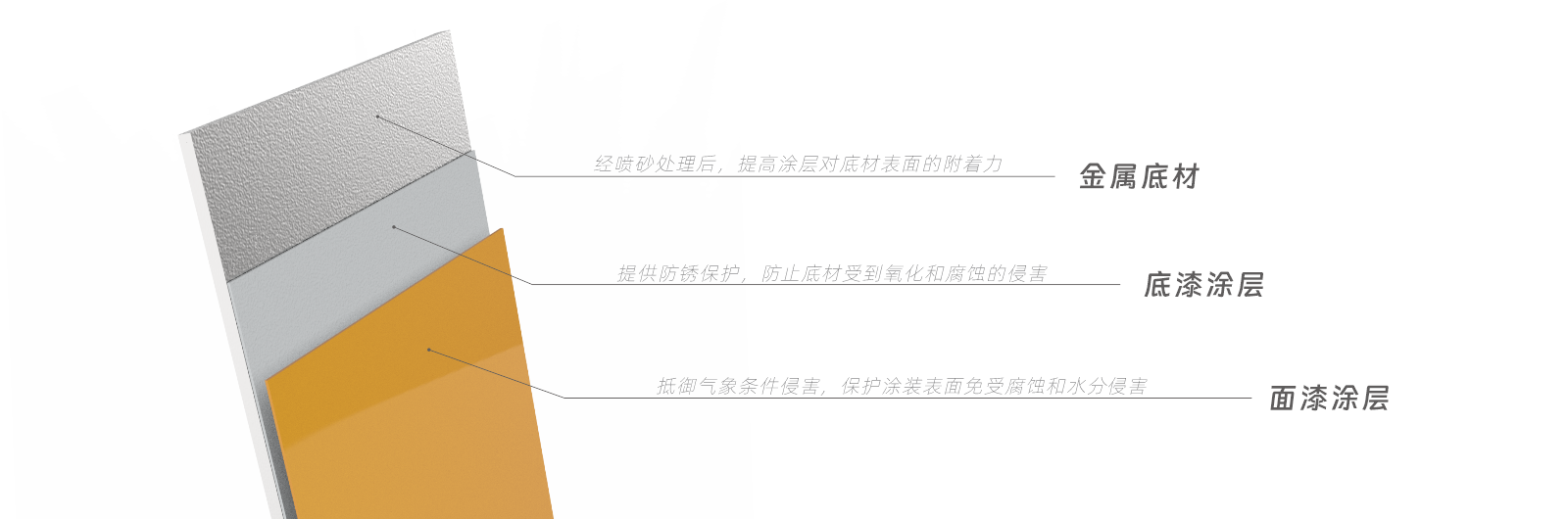

Coating System

Application Method

Application Temperature: 5°C to 40°C

Mixing: Stir thoroughly using power tools or manual tools to ensure even mixing.

Mixing ratio: Single-component coating.

Application Methods: Airless spraying, air spraying, brushing, or rolling (specialized).

| Application Method | Nozzle Size | Outlet Pressure | Thinning Ratio |

| Airless Spraying | 0.43mm-0.53mm | 10-15Mpa |

20-27% |

| Air Spraying | ---- | ---- |

38-46% |

| Brushing/Rolling | ---- | ---- |

27-38% |

| Thinner | Acrylic Thinner |

Drying Time & Recoating Interval

| Temperature | 5℃ | 20℃ | 30℃ |

| Touch Dry | 1hrs | 30mins | 20mins |

Semi-Hard Dry | 6hrs | 3hrs | 2hrs |

| Minimum Recoat Interval | 12hrs | 6hrs | 4hrs |

Maximum Recoat Interval |

|

Surface Preparation

The steel surface to be coated must be thoroughly cleaned of oil, scale, rust, and old coatings. This can be achieved through methods such as shot blasting or sandblasting, reaching the Swedish rust removal standard Sa2.5 level, with a roughness of 30–70 μm. Alternatively, manual rust removal methods can be used to reach the Swedish rust removal standard St3 level, with a roughness of 30–70 μm.

Safety Measures

1、Avoid contact with skin and eyes.

2、If paint comes into contact with skin, wash with warm water or an appropriate cleaning agent. If paint comes into contact with eyes, rinse thoroughly with water and seek medical attention immediately.

3、Ensure adequate ventilation.

4、The paint contains flammable substances. Keep away from sparks and prohibit smoking in the vicinity.

5、Comply with all health and safety regulations on-site.

Storage

Store in a dry and cool environment, away from heat sources and open flames. Keep the container tightly sealed.

Shelf life: 12 months from the date of production (at 25°C).

Please Notice

Since the conditions of product use are beyond our control, the information provided here does not constitute a warranty. We are only responsible for the selection of products. Due to the continuous development of our products and production processes, the content of this manual may be updated at any time. All information herein is subject to our confirmation. Before using the product, please ensure that you have the latest version of the manual.