1 Background

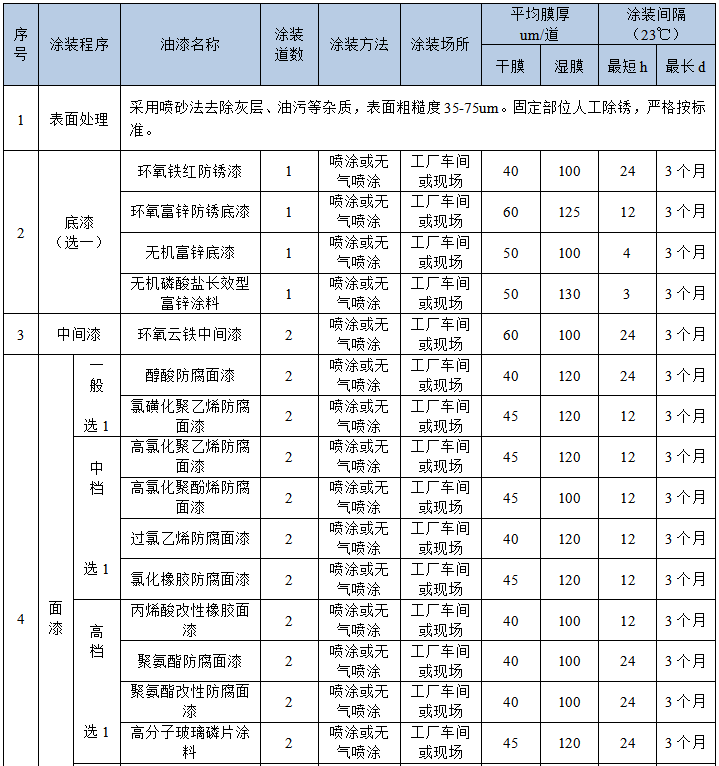

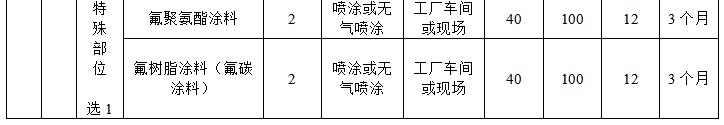

(1)Based on the requirements of design institutes in the oil, petrochemical, metallurgy, and power industries, as well as other relevant fields, and considering the corrosive environments, we have referenced the practical performance of our factory's heavy-duty anti-corrosion coatings in applications such as oil refineries, petrochemical plants, metallurgical facilities, thermal power stations, hydropower stations, and bridges. We recommend using high-performance heavy-duty anti-corrosion coatings as the preferred solution for steel structure corrosion protection.

(2)To prevent corrosion of steel structures, extend their service life, and ensure the quality of the paint film, the coating application must strictly adhere to the requirements outlined in this plan.

(3)During the coating application process, surface preparation and painting operations must comply with the product instructions specified in this plan to guarantee optimal anti-corrosion performance.

2 Surface Preparation Quality Requirements

For ordinary steel, sandblasting should be used to remove rust, scale, and other contaminants. The quality control of surface preparation must meet the Sa2.5 standard as specified in GB8923 "《Rust Grades and Preparation Grades of Steel Surfaces Before Coating》. The surface roughness should be between 35-75 μm. After sandblasting, all dust must be thoroughly removed. For fixed or hard-to-reach areas, manual rust removal is acceptable but must strictly follow the above standards.