Product Features

Effectively seals the zinc particles in the Cold Galvanizing Primer, preventing oxidation and discoloration of the zinc, thereby extending the service life of the coating.

Exhibits excellent resistance to acids, alkalis, salt spray, and more, providing effective protection for metal surfaces against chemical and atmospheric corrosion.

Demonstrates strong adhesion, flexibility, and abrasion resistance, capable of withstanding certain degrees of mechanical impact and wear.

The coating boasts a high-gloss finish with superior decorative effects, imparting an aesthetically pleasing appearance to metal surfaces.

Application Scope

The Cold Galvanizing Sealer is suitable for use in conjunction with Cold Galvanizing Primer as an anti-corrosion coating for surfaces such as steel structures and metal components.

It is particularly well-suited for metal surfaces that are exposed to atmospheric conditions over extended periods, including but not limited to: buildings and facilities, bridges and street lamps, electrical installations, transportation vehicles, and mechanical equipment.

Technical Parameters

Color

| Silver |

| Volume Solids | 24% |

Flashpoint

| Above 23°C |

| Coating film thickness | Dry film:15-20μm/coat Wet film: 63-83μm/coat |

| Theoretical Coating Rate | 0.098kg/m2/20μm Depends on surface preparation, environmental conditions, application methods, and other factors. |

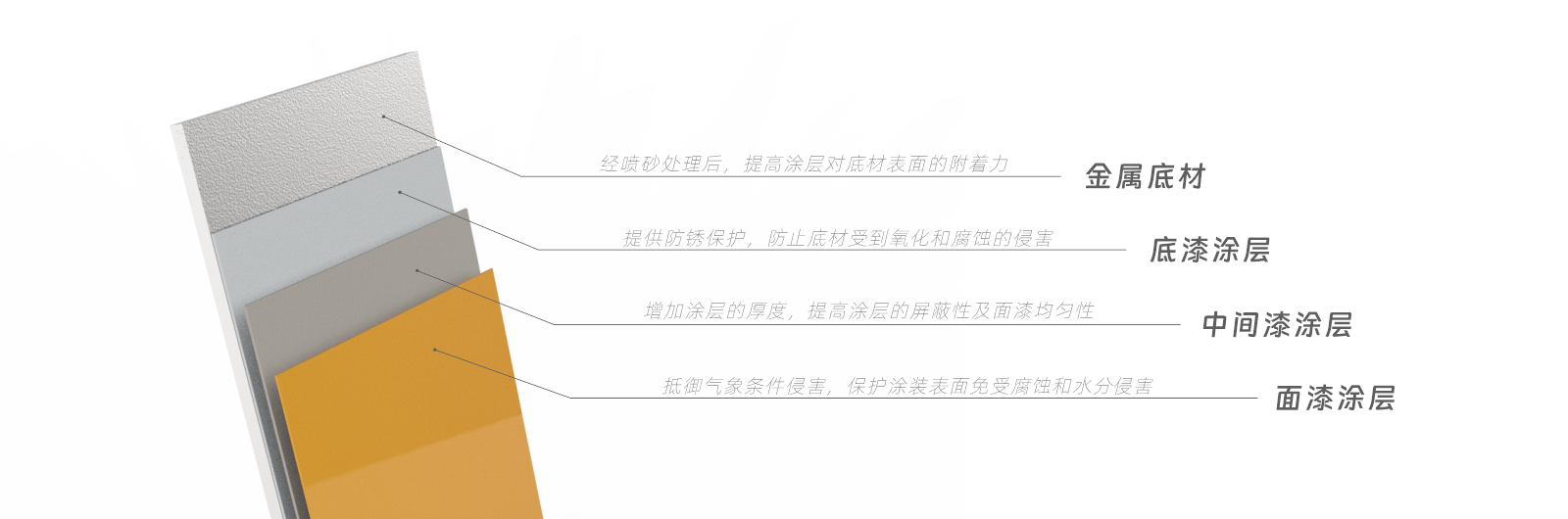

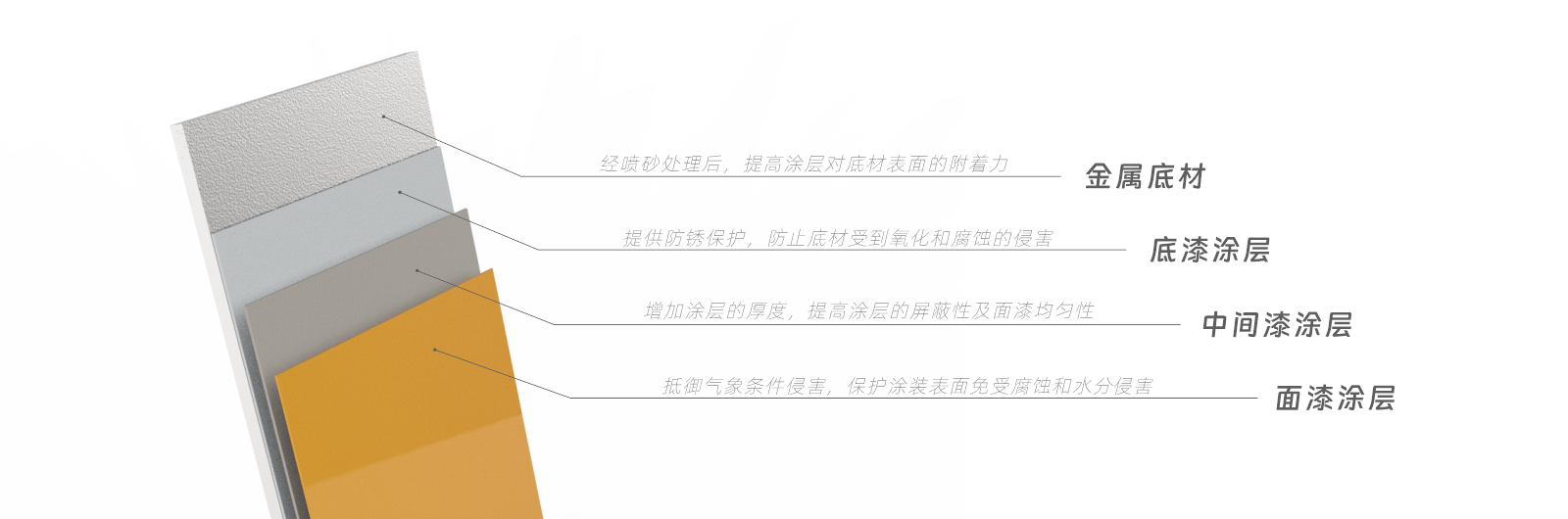

Coating System

To be used in conjunction with Cold Galvanizing Primer.

Construction Method

Application Temperature: -5°C to 40°C

Mixing: Stir thoroughly using a power tool to ensure even consistency.

Mixing Ratio: Single-component coating.

| Construction method | Nozzle Size | Outlet Pressure

| Thinning Ratio |

| Airless Spray | 0.43mm-0.53mm | 10-15Mpa | 12-23% |

| Air Spray | ---- | ---- | 33-42% |

| Brushing/ Rolling | ---- | ---- | 23-33% |

Drying Time & Recoating Interval

Temperature

| 5℃ | 20℃ | 30℃ |

| Touch Dry | 1hr | 40mins | 30mins |

semi-hard dry

| 6hrs | 3hrs | 2hrs |

| Minimum Recoat Interval | 12hrs | 6hrs | 4hrs |

| Maximum Recoat Interval | Unlimited |

Surface Treatment:

The steel surface to be coated must be thoroughly cleaned of oil, scale, rust, and old coatings. This can be achieved through methods such as shot blasting or sandblasting, reaching the Swedish rust removal standard Sa2.5, with a roughness of 30~70μm. Alternatively, manual rust removal methods can be employed to achieve the Swedish rust removal standard St3, with a roughness of 30~70μm.

Safety Measures:

1、Avoid contact with skin and eyes.

2、If paint comes into contact with skin, wash with warm water or an appropriate cleaning agent. If paint comes into contact with eyes, rinse thoroughly with water and seek medical attention immediately.

3、Ensure adequate ventilation.

4、The paint contains flammable substances. Keep away from sparks and prohibit smoking in the vicinity.

5、Comply with all health and safety regulations on-site.

Storage:

Store in a dry and cool environment, away from heat sources and open flames. Keep the container tightly sealed.

Shelf life: 12 months from the date of production (at 25°C).

Please Notice:

Since the conditions of use of the products are beyond our control, the information contained herein is provided without warranty, i.e., the buyer is liable only for the selection of the products. Due to the continuous development of our products and production processes, the contents of this manual are subject to change at any time, and all information herein is subject to our confirmation. Please make sure that you have the latest version of this manual before using the product.