A versatile chlorinated rubber anti-corrosion primer composed of chlorinated rubber and anti-corrosive pigments.

Used for steel structure surfaces in both submerged and non-submerged areas.

A versatile chlorinated rubber anti-corrosion primer composed of chlorinated rubber and anti-corrosive pigments.

Used for steel structure surfaces in both submerged and non-submerged areas.

Excellent Chemical Resistance: Withstands corrosion from various chemical media, including acids, alkalis, salts, and oils.

Superior Water and Weather Resistance: Suitable for long-term outdoor use, resistant to sunlight, rain, and freeze-thaw cycles.

Strong Adhesion and Sealing Properties: Adheres firmly to various metal surfaces and effectively blocks contact between corrosive media and the substrate.

|  |  |  |

|  |  |  |

Property | Alkyd Primer | Epoxy Primer | Chlorinated Rubber Primer |

| Application | Single-component, slow drying | Two-component, requires hardener | Single-component, fast drying |

| Chemical Resistance | Poor for heavy corrosion protection | Excellent | Excellent |

| Water Resistance | Good | Excellent | Excellent |

| Weather Resistance | Good | Poor | Excellent |

| Compatibility | Compatible only with alkyd paints | Compatible with various topcoats | Compatible with various topcoats |

Chlorinated rubber anti-corrosion coatings are suitable for use in C3-C5 medium to severe corrosion environments, applied to steel structure surfaces in both submerged and non-submerged areas.

Atmospheric Environments: Industrial plants, bridges, power transmission lines, etc.

Marine Environments: Ships, docks, and offshore platforms.

Underground Environments: Buried pipelines and storage tanks.

Chemical Environments: Petrochemical plants, acid/alkali manufacturing sites, and electroplating facilities.

|  |  |

|  |  |

| Color | Silver and Iron Red |

| Volume Solids | 48-55 |

| Flash Point | Above 25°C |

| Coating Thickness | Dry Film: 40-90 µm/coat; Wet Film: 82-184 µm/coat |

| Theoretical Coverage | 0.184 kg/m²/70 µm Depends on surface preparation, environmental conditions, application methods, etc. |

Chlorinated rubber primer is typically used in conjunction with chlorinated rubber topcoat to achieve optimal anti-corrosion performance.

Application Temperature: -5°C to 40°C.

Mixing: Ensure thorough mixing using power tools or manual methods until the coating is uniform.

Mixing Ratio: Single-component formulation (no mixing required).

Application Techniques: Airless spraying, conventional air spraying, brushing, or roller coating (for specialized use).

| Application Method | Nozzle Size | Outlet Pressure | Thinning Ratio |

| Airless Spraying | 0.43mm-0.53mm | 10-15Mpa | 0-10% |

| Air Spraying | ---- | ---- | 0-10% |

| Brushing/Rolling | ---- | ---- | 0-10% |

Drying Time & Recoating Interval

| Temperature | 5℃ | 20℃ | 30℃ |

| Touch Dry | 1hrs | 30mins | 15mins |

| Semi-Hard Dry | 6hrs | 4hrs | 2hrs |

| Minimum Recoat Interval | 6hrs | 4hrs | 2hrs |

| Maximum Recoat Interval | Unlimited | ||

Surface Preparation:

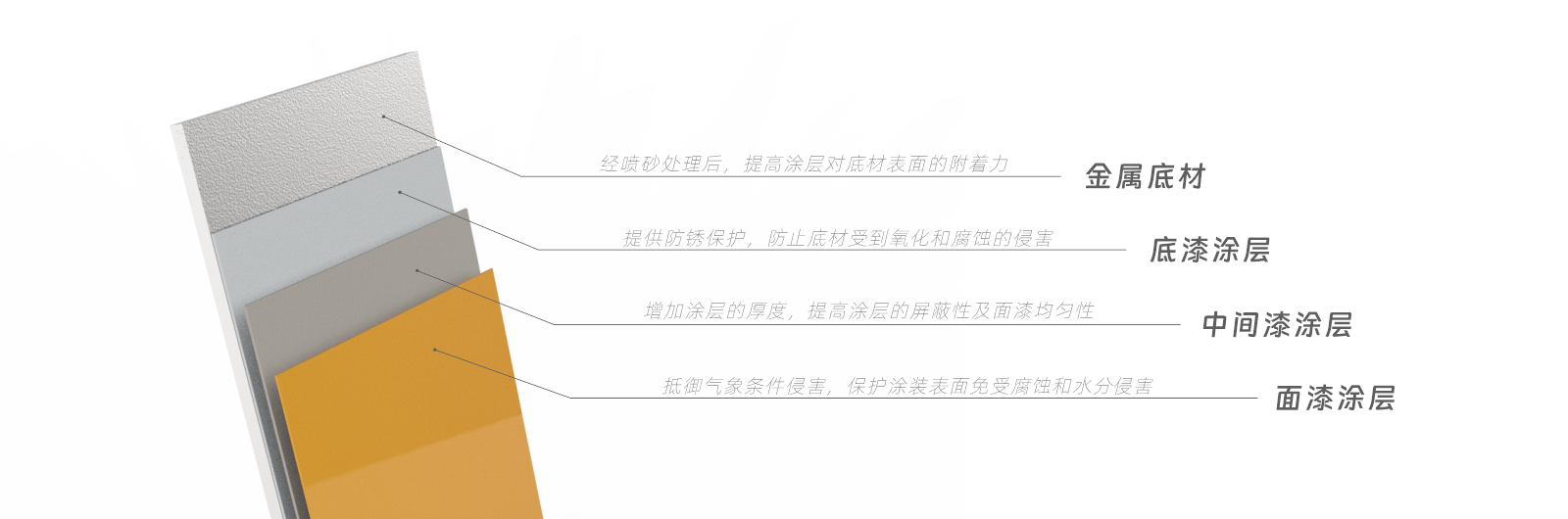

The steel surface to be coated must be thoroughly cleaned of oil, scale, rust, and old coatings. This can be achieved through shot blasting or sandblasting to meet the Swedish standard Sa2.5, with a roughness of 30~70 µm. Alternatively, manual cleaning methods can be used to achieve the Swedish standard St3, with a roughness of 30~70 µm.

Safety Measures:

1.Avoid contact with skin and eyes.

2.If paint comes into contact with skin, wash with warm water or an appropriate cleaner. If paint gets into the eyes, rinse immediately with plenty of water and seek medical attention.

3.Ensure proper ventilation.

4.The paint contains flammable substances. Keep away from sparks and prohibit smoking in the vicinity.

5.Follow all health and safety regulations on-site.

Storage:

Store in a dry and cool environment, away from heat sources and open flames. Keep the container tightly sealed.

Shelf life: 12 months from the date of production (at 25°C).

Important Notice:

As product usage conditions are beyond our control, the information provided is without warranty, and our responsibility is limited to product selection. Due to ongoing improvements in our products and processes, this manual may be updated periodically. All information is subject to our confirmation. Before use, ensure you have the latest version of the manual.

15602001474

15602001474