Product Features

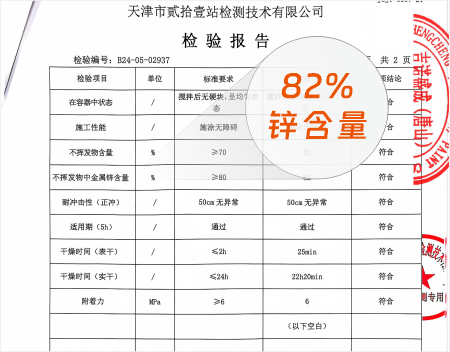

With a zinc content of up to 80% in the film, it provides strong electrochemical cathodic protection for metal substrates, effectively blocking corrosion.

It exhibits excellent resistance to acids, alkalis, salt spray, seawater, and atmospheric conditions, effectively withstanding erosion from various harsh environments and ensuring long-lasting performance.

It adheres well to metal substrates, forming a dense coating that is resistant to peeling, effectively protecting the metal surface from corrosion.

It is easy to apply and can be applied by brushing, rolling, or spraying. It is free of heavy metals such as lead, cadmium, and mercury, meeting environmental standards and ensuring safety and non-toxicity.

Product Comparison

| Property | Epoxy Zinc-Rich Primer (Type 1) | Epoxy Zinc-Rich Primer (Type 2) | Epoxy Zinc-Rich Primer (Type 3) |

| Zinc Content in Non-Volatiles, % | 80 | 70 | 60 |

| Salt Spray Resistance,h | 600

| 400 | 200 |

| Drying Time,h | 24 | 24 | 24 |

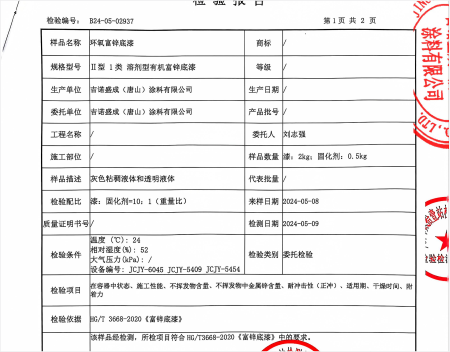

The above data is based on the HG/T 3668-2020 standard.

Inspection Report

Application Scope

Epoxy zinc-rich primer is widely used on pre-treated steel surfaces as the base layer of an epoxy zinc-rich coating system. It effectively enhances the anti-corrosion performance and durability of the coating system.

It is suitable for corrosion protection in various types of steel structures, such as: bridge engineering, power facilities, petrochemical equipment, shipbuilding industry, steel structure buildings, and pipeline storage.

Technical Parameters

| Color | Gray |

| Volume Solids | 55% |

| Flash Point | Above 18°C |

| Coating Thickness | Dry film:30-70 µm/coat; Wet film:55-128 µm/coat |

| Theoretical Coverage | 0.202kg/m²/50 µm |

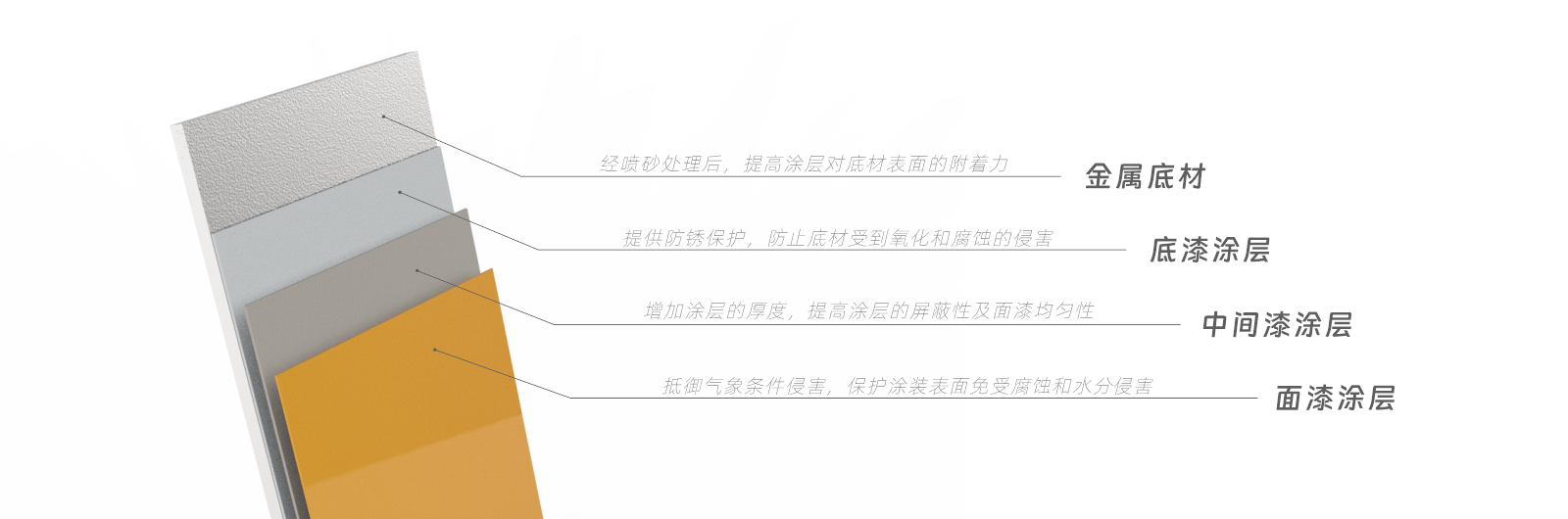

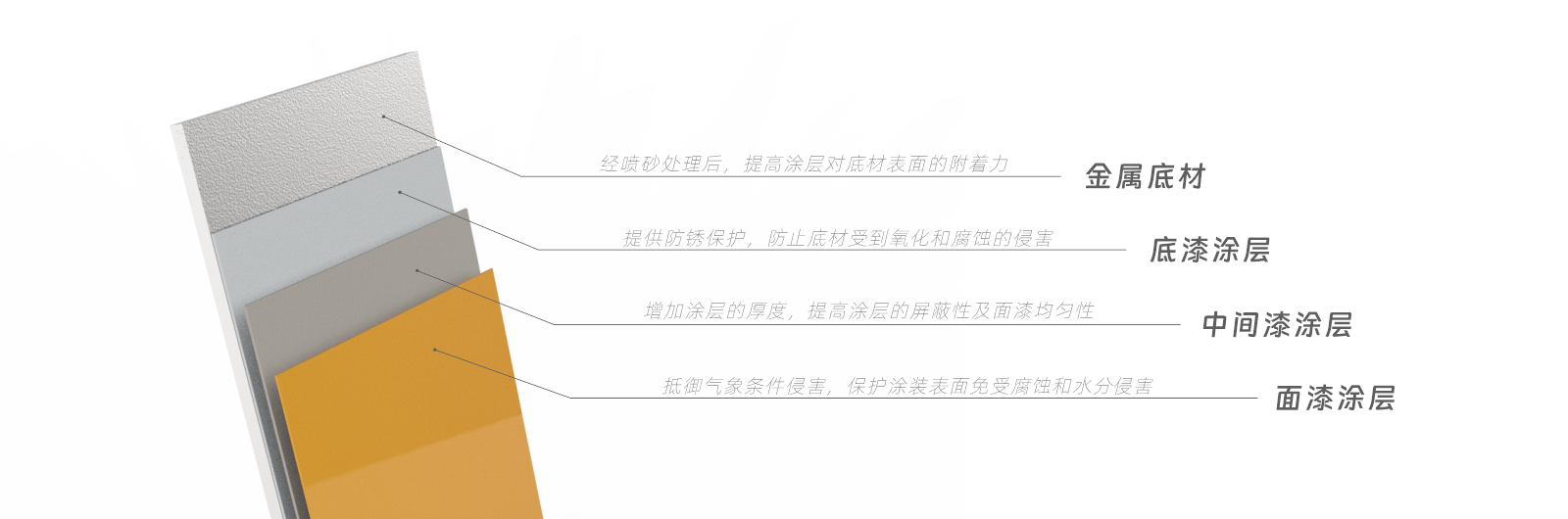

Coating System

To fully leverage its excellent anti-corrosion performance, it is typically recommended to use a topcoat in conjunction, forming a complete coating system.

Epoxy Topcoat: Offers excellent chemical resistance, abrasion resistance, and water resistance, making it suitable for harsh environments.

Acrylic Polyurethane Topcoat: Provides excellent weather resistance and decorative properties, making it ideal for outdoor environments.

Fluorocarbon Topcoat: Exhibits superior weather resistance, chemical resistance, and corrosion resistance, making it suitable for metal surfaces that are exposed to harsh environments for extended periods

Application Methods

Application Temperature: -5°C t ~ 40°C;

Mixing: Stir thoroughly using power tools or manual tools to ensure even mixing;

Mixing Ratio: Base/ Hardener = 10/1 (by weight);

Application Methods: Airless spraying, air spraying, brushing, or rolling (specialized).

| Application Method | Nozzle Size | Outlet Pressure | Thinning Ratio |

| Airless Spraying | 0.43mm-0.53mm | 10-15Mpa | 0-2% |

| Air Spraying | ----- | ----- | 0-5% |

| Brushing/Rolling | ----- | ----- | 0-3% |

Drying Time & Recoating Interval

| Temperature | 5℃ | 20℃ | 30℃ |

| Touch Dry | 30min | 20min | 10mins |

| Semi-Hard Dry | 6hrs | 3hrs | 1hr |

| Minimum Recoat Interval | 6hrs | 3hrs | 3hrs |

| Maximum Recoat Interval |

|

|

|

Surface Preparation:

The steel surface to be coated must be thoroughly cleaned of oil, scale, rust, and old coatings. This can be achieved through shot blasting or sandblasting to meet the Swedish rust removal standard Sa2.5, with a roughness of 30~70μm. Alternatively, manual rust removal methods can be used to meet the Swedish rust removal standard St3, with a roughness of 30~70μm.

Safety Measures:

1、Avoid contact with skin and eyes.

2、If paint comes into contact with skin, wash with warm water or an appropriate cleaning agent. If paint comes into contact with eyes, rinse thoroughly with water and seek medical attention immediately.

3、Ensure adequate ventilation.

4、The paint contains flammable substances. Keep away from sparks and prohibit smoking in the vicinity.

5、Comply with all health and safety regulations on-site.

Storage:

Store in a dry and cool environment, away from heat sources and open flames. Keep the container tightly sealed.

Shelf life: 12 months from the date of production (at 25°C).

Please Notice:

Since the conditions of product use are beyond our control, the information provided here does not constitute a warranty. We are only responsible for the selection of products. Due to the continuous development of our products and production processes, the content of this manual may be updated at any time. All information herein is subject to our confirmation. Before using the product, please ensure that you have the latest version of the manual.